Application of polyurethane spray foam insulation on cables with non-metallic covering

Information Bulletin

Application of polyurethane spray foam insulation on cables with non-metallic covering

March 4, 2025

Reference Number:

B-E3 070327 1

Revision Number:

Revision 2

This Information Bulletin supersedes B-E3 060815 3 issued on August 15, 2006.

Topic: Polyurethane Spray Foam Insulation

Attention: Building owners, general contractors, applicators of polyurethane spray foam insulation, electrical contractors.

The reference to "cable" in this bulletin has the same meaning as defined in Section 0 of the BC Electrical Code. Examples of electrical cables with a non-metallic covering are non-metallic sheathed cables and non-metallic jacketed cables.

This bulletin provides information to all stakeholders, including applicators of polyurethane spray foam insulation. Strict adherence to the manufacturer's application instructions is necessary when this type of product is applied in contact with electrical cables with a non-metallic covering. Non-conformance with these requirements could result in a condition known as 'reversion', which results in a hard lacquer-like coating. This lacquer-like coating may bond to the non-metallic cable sheath resulting in damage to the cable sheath when mechanical strain is applied to the cable. It is essential to pay particular attention to the required ambient and product application temperatures specified.

It has been observed that where reversion occurs, the resulting lacquer-like coating bonds tightly to the non-metallic cable. When mechanical strain is subsequently applied to this section of cable, the lacquer-like coating may break. Due to the tight bond between the lacquer-like coating and the non-metallic cable, this may cause the cable sheath to be pulled apart or crack. It should be noted that damage to cable sheaths has only been observed where application has resulted in ‘reversion’ and mechanical stress has subsequently been applied to the cables. This product has not been observed as having caused direct damage to the cable or cable sheaths due to contact. Damage has only been observed where the two conditions noted above have been met.

It is strongly recommended that moving, relocating or re-use of cables after they have had polyurethane spray foam insulation applied to them be avoided. Any such work should only be performed by a registered electrical contractor. Contact with any substance, including polyurethane spray foam insulation, could compromise the flexibility requirements of Canadian Standards Association CAN/CSA – C22.2 No. 48-09 (R2014) which requires these cables to be bent around a radius of 4 times the thickness of a 2 conductor cable and six times the diameter of a twisted conductor cable, without fracturing or opening up of the insulation or jacket.

This photograph shows a typical spray foam installation.

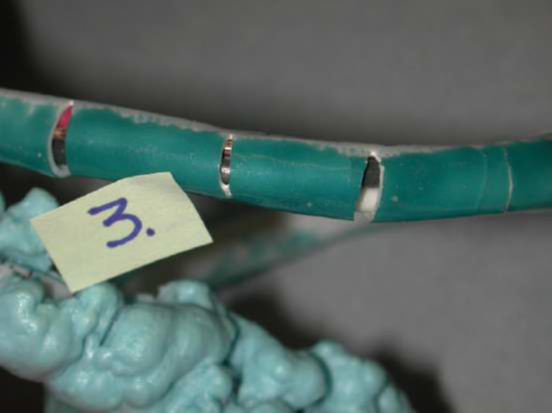

This photograph shows an example of damage to cable sheath.

Vicky Kang

Manager, Energy

Provincial Safety Manager, Electrical

References:

Safety Standards Act Electrical Safety Regulation

Safety Standards General Regulation

Safety Standards Act Repeal and Transitional Provisions Regulations