Ammonia

Annual State of Safety 2023

Taking Action on Ammonia Safety

Every day, kids across BC skate onto the rink for hockey practice. Similarly, each day, workers across the province clock in to work at cold processing plants and warehouses in the agriculture and food industries. To many, this has become second nature. But few of us stop to consider the equipment used to make these activities possible.

But like many chemicals and regulated equipment, when improperly handled, ammonia can pose a deadly safety risk. Ammonia can be corrosive to the skin, eyes, and lungs upon contact, and ammonia release incidents can quickly turn fatal. When ammonia is depressurized and released, it rapidly expands from a liquid to a gas, which means it spreads extremely quickly and can put entire communities at risk.

In 2017, there was an ammonia release at the Fernie Memorial Arena which caused three fatalities, as well as the evacuation of 95 residents from 55 nearby homes. A similar incident occurred at a meat processing plant in Langley, BC, when a ruptured heat exchanger released an estimated 485 to 1,500 lbs of ammonia from the refrigeration system, and resulted in an extensive area evacuation for two days.

In 2023, we identified ammonia release as one of the Top 5 Safety Risks from regulated technologies in BC. The rankings are based on the likelihood of an incident taking place, as well as the severity of consequences such as injury or damage following an incident.

Kamloops Ammonia Release Incident

Exposure to a large amount of ammonia can be fatal, as we’ve seen in an ice making facility in the Mount Paul Industrial Park located on Tḱemlúps te Secwépemc land in Kamloops, in May 2022. During disassembly of an ammonia system at the facility, a ball valve holding back pressurized ammonia for the entire system was opened. This resulted in a significant amount of ammonia being released, causing multiple exposures, including one fatality, an evacuation, and the temporary shutdown of nearby businesses.

Upon investigation, we discovered that ammonia hadn’t been removed from the refrigeration system prior to its disassembly, but those working on the disassembly mistakenly believed that the system had been previously emptied.

Several contributing factors led to this incident, including miscommunication, staff changes, and failure to safely check for the presence of ammonia before disassembly.

In 2023, Technical Safety BC published an extensive investigation report on the findings of this incident.

Learn more about the recommendations coming from this investigation or view the full investigation report.

"There are many complex factors, outside of the ammonia gas itself, that may contribute to an incident."

Changes to the Mechanical Refrigeration Code

Following the Kamloops incident, we actively worked with the Canadian Standards Association (CSA) B52 code committee to incorporate recommendations from this investigation into code. This resulted in a proposed change to the code, including the introduction of new requirements for decommissioning refrigeration systems.

We also evaluated recommendations from the investigation and drafted a directive to further clarify the technical requirements, roles, and responsibilities associated with decommissioning activities. The directive is expected to be issued in 2024.

Engaging with Industry

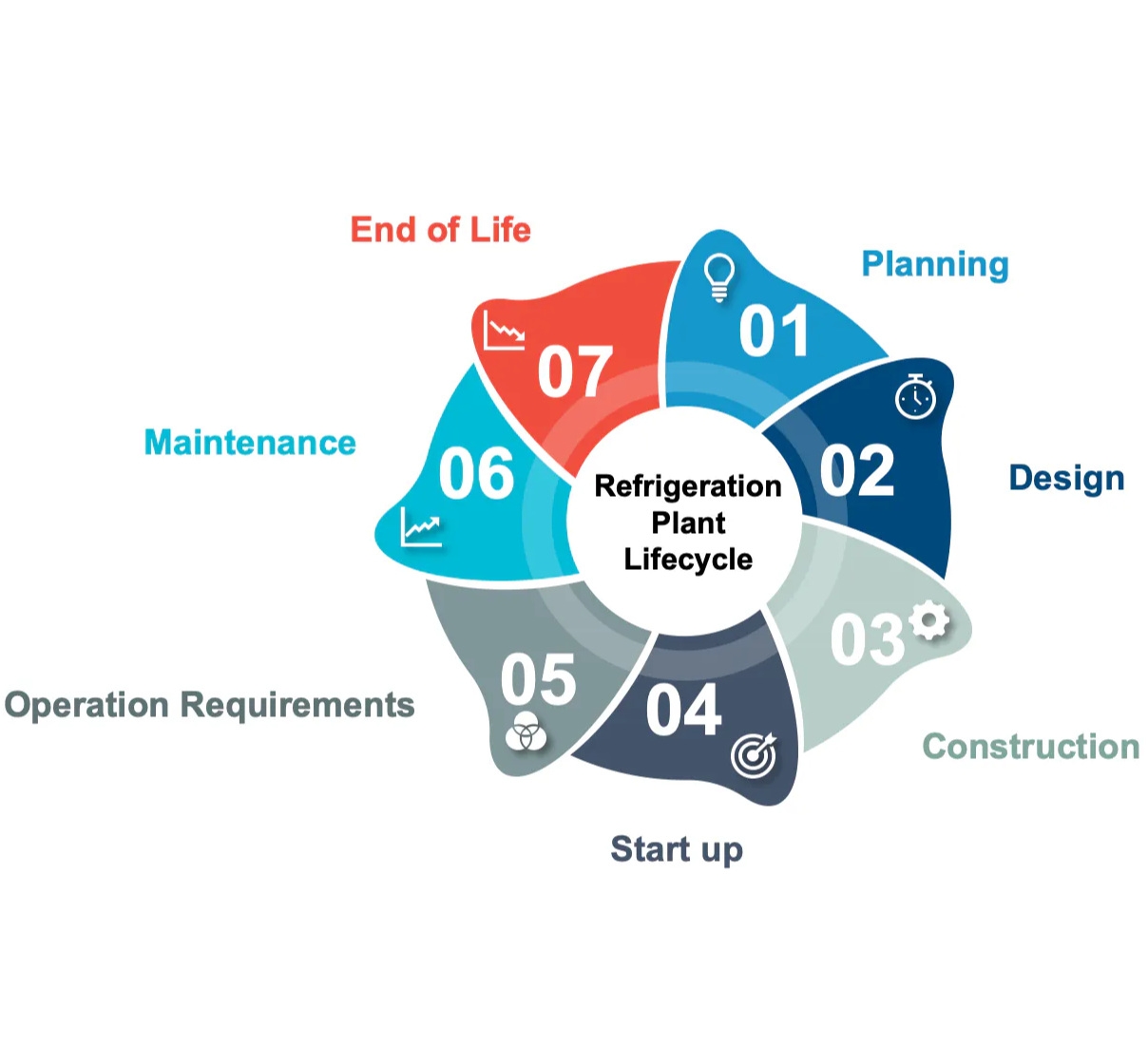

We shared the findings of this incident with the Ammonia Safety Awareness Program working group. This group of industry professionals assisted in the creation of a new curriculum for the Ammonia Safety Awareness Program, which includes best practices for maintaining ammonia refrigeration equipment and systems across their lifecycle, as a response to an earlier tragedy at Fernie Memorial Arena.

The program supports owners and operators in their decision-making to ensure adequate employee training per regulation, and that replacement plans are made for equipment reaching end-of-life. As of 2024, over 453 people have taken this course.

Ammonia Release Remains a Risk

The severity of an ammonia release, as we saw in Kamloops, can be catastrophic. On a smaller level, exposure to ammonia can still cause serious injuries.

As we’ve learned from our incident investigations, there are many complex factors outside of the ammonia gas itself that may contribute to an incident, including:

- communication between those working on the equipment,

- proper documentation of work, prioritizing equipment maintenance,

- funding for equipment upgrades and decisions made by workers, owners, and operators.

When used and managed correctly, ammonia is a safe solution for cooling. We continue to track incidents related to ammonia in our risk register as we work with safety partners and the industry to mitigate hazards that may put British Columbians at risk.

"We continue to work with safety partners and industry to mitigate risks and hazards that may put British Columbians at risk."

You Might Be Interested In

Building Confidence

Learn about emerging risks. See how we’re improving the client experience and enforcing against those who work outside of the safety system.

Learn MoreSafety Engagement

We provide technical training and education to support our partners. We also work to influence people in the safety system to make safety-minded decisions.

Learn MoreData and Trends

Find key statistics on permits, incidents, injuries, assessments, and more.

Learn More