Boiler Plant Operating Permits

We provide operating permits for entire boiler plants, separate from the individual boiler operating permit(s) for specific equipment.

Overview

A plant is defined as a boiler, or assembly of boilers (and any ancillary vessels) connected to a common heating, steam, or power system through a single header. A plant can be as small as a single boiler or can be made up of an array of pressure equipment on a premise.

Boiler Plant Operating Permits are separate from the individual boiler operating permits and are focused on the registration of the entire plant or system of interconnected boilers.

Boiler Plant Permit Requirements

Owners of boiler plants that are fifth class and above, as well as oil well boiler plants, need to register their plants and obtain a plant operating permit. Pressure plants (plants that only have pressure vessels attached, and no other boilers or types of equipment) do not require a plant operating permit.

Boiler plant owners in BC are required to obtain a boiler plant operating permit for the following plant types:

- 1st, 2nd, 3rd, 4th, and 5th class plants

- Oil well plants

The permit is required for all plants listed above, including those registered as a "special status plant.” The requirement is outlined in section 62.1 of the Power Engineers, Boiler, Pressure Vessel & Refrigeration Safety Regulation.

Boiler plant operating permits will help those who operate plants:

- gain confirmation of compliance;

- gain knowledge of required operator qualifications;

- more effectively oversee their regulated boiler equipment; and

- track a power engineers' firing time (hours of professional work) in the plants they operate.

Boiler plant operating permits also help us to:

- understand the connected set of boiler equipment as a system;

- better assess areas of risk; and

- clarify plant classification and staffing requirements with owners, users, and individuals who oversee plant operations.

Who Should Apply?

The first step in determining eligibility is to verify the plant types. The plant type is critical, since it dictates the plant classification, and therefore also the staffing requirements.

All of the following plants should apply online for a plant operating permit:

- All high-pressure thermal fluid plants above 10 m2.

- All low-pressure thermal fluid plants above 150 m2.

- All plants producing high pressure steam [>15 psi pressure relief device settings], which are larger than 10 m2.

- All plants producing low pressure steam [<= 15 psi pressure relief device settings], which are larger than 30 m2.

- All plants using hot water or glycol mixture, which are larger than 150 m2

- All oil well plants.

Use our Boiler Plant Registration Self-Assessment Guide and plant type and classification calculator to help you evaluate your systems and equipment to determine if a boiler plant operating permit is required for your facility.

Before Applying

Please follow the instructions below before you apply. This application should be submitted by the supervising Power Engineer.

- Obtain a Technical Safety BC online account. If you haven’t registered, please sign up here.

- After logging in, ensure the account and equipment information on your boiler operating permit is up to date before starting the application process. If you need to update your boiler unit information, email details to us at boileroperatingpermits@technicalsafetybc.ca. Only move forward with your application after the details have been updated.

- Verify that your boiler operating permits are current and active.

- Gather legible images of the ASME stampings and manufacturer nameplates for all boiler units connected to your classed headers.

- The application requires a designated Chief Engineer / Primary Operator / Oil Well Operator to be named. Be prepared to provide your legal name and Power Engineer certificate number.

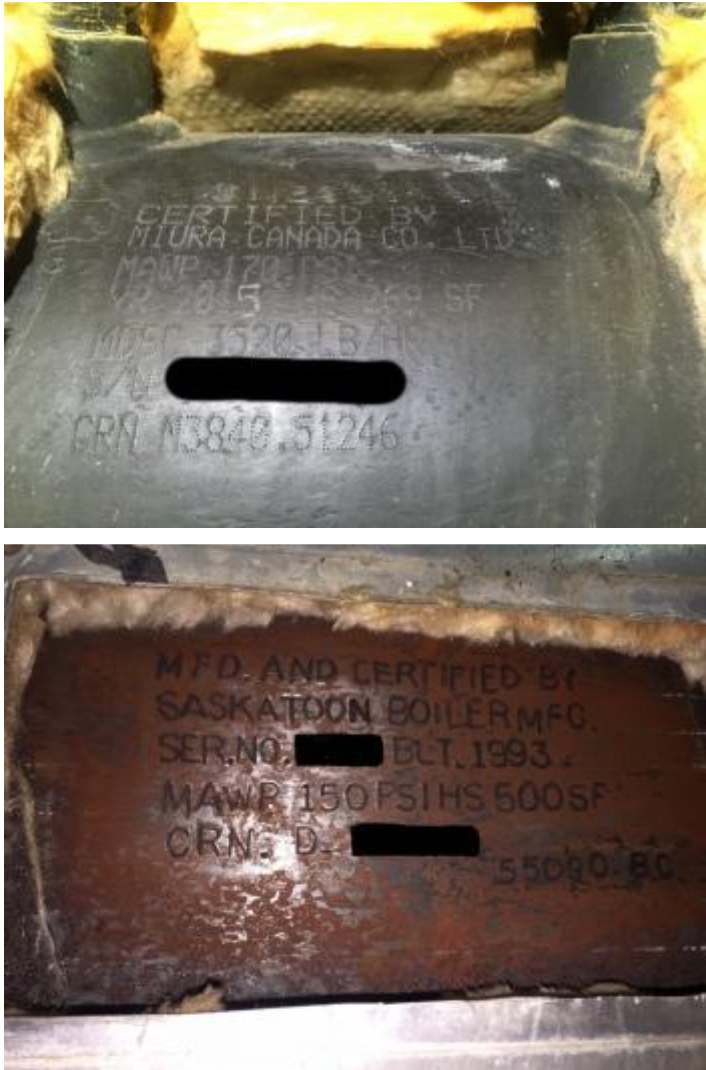

ASME Stampings and Nameplate Requirements

As part of processing the application, please provide the following information.

For all boilers connected to the headers under a plant operating permit:

- Pictures of ASME stamping or manufacturers' data report (see MDR example);

- Picture of manufacturer nameplate; and

- Picture of mechanical high temperature cutout.

For above headers using thermal fluid:

- Safety Data Sheet (Thermal Fluid); and

- Manufacturer's Technical Specification (Thermal Fluid).

If you have economizer(s), there could be more than one nameplate on a boiler. If there is an economizer that is isolable, please include the above information for economizers as well.

For each picture, please comply with the following:

Locating the ASME stamping:

- Manufacturer nameplates are generally easier to locate than the ASME stamping.

- The ASME information is generally stamped on the drum (so that, even with component changes, the stamping is least likely to be removed). See ASME BPVC.I-2017 PG-111 “Location of Stampings” for more details.

- Sometimes, there is a cut out flap in the insulation and you’ll have to open the flap to see the stamp beneath on the surface of the drum.

- If you still cannot find it, a quick call to the manufacturer could help you locate it.

Ensure all the information is readable. Due to deterioration (corrosion, dust), the readability of stampings decreases with boiler age. If the stampings are not clear, you can clean the area with a wire brush and/or run a black Sharpie, white chalk, or white marker along the stampings to help them stand out clearly. Similarly, some clients have success using a wax pencil on the hot boiler, melting the wax, and then wiping it off, which can leave a clear image.

Photo Requirements

- Please include all stamped numbers, letters, and logos in the picture. Even if a single letter or number is stamped away from the rest, include it in the picture.

- Unless absolutely necessary for completeness and clarity, avoid sending multiple photos of parts of the same nameplate or stamping.

- ASME stampings typically include: CRN number, National Board number [NB], Designators [e.g., S, M, E, W], serial number, heating surface area, MAWP, MAWT, minimum pressure relief valve capacity / maximum design steaming capacity [MDSC], year manufactured.

- Glares from camera flashes or lighting may make reading impossible, so please look out for that. Use appropriate background lighting to prevent glares.

Email Your Photos

- For every picture attached to the email, make sure you can unambiguously read the least clear stampings/printings.

- Please do not embed photos in an email, but attach them as files named with your boiler name and type of information, e.g., Boiler #1 ASME, “Boiler #1 Nameplate, “Economizer 1, etc.

- To assist with the registration process, ensure each file is named so that it can be identified both with the piece of equipment and the type of document. The equipment name can be based on your own reference or a Technical Safety BC identifier, such as permit number. For example, “Heater S/No. 16-1327 – Nameplate” or “BPV-######-2017 – High Temperature Cutout”.

If you need to provide more than 10 files, please send them to boilerplantreg@technicalsafetybc.ca with the same naming standards for each file. Please do not submit files through this form if they are instead emailed to this email address.

Apply for a Permit

While information is required for all class headers on a site, a plant operating permit will be issued for the highest class header on the site.

There are two ways plant owners can apply for their boiler plant operating permit(s):

- Complete and submit the Boiler Plant Operating Permit Application Form 1688 to boilerplantreg@technicalsafetybc.ca, or

- Log into your client portal account and register your plant from the unit list. For more information on how to register through the online client portal, follow the self-registration guide on our webpage.

As a part of the application submission or online registration, plant owners must also submit supporting documentation to verify the plant type and classification. For each boiler associated with your plant, the following information must be submitted with the application or online registration:

Pictures of each manufacturer’s nameplate and ASME stamping.

If photos of the ASME stamping are not available, the Manufacturers Data Report (MDR) may be submitted in lieu.

If you have more than one site, you will need to apply for each site separately until you have applied to register all of your sites. Once our assessment is complete, we will send out the Plant Operating Permit by email or mail, based on your preferred method of contact.

Frequently Asked Questions About Boiler Plant Operating Permits

Special Status Plant

I have a special status plant. Do I still need to obtain a plant operating permit?

Yes, provided the plant qualifies. You will be required to register and obtain a plant operating permit, even if you are already classified as a general supervision or risk-assessed plant.

Why Do I Need a Plant Permit?

We have aligned our permitting practices with other provincial jurisdictions. As such, we require the registration of a plant as a whole operating system (e.g., a single large boiler, or an array of multiple small boilers). This will confirm and classify its use and assignment of certified operators. The plant operating permit records the size, assembly, configuration, and staffing, accurately confirming and displaying your compliance to BC’s regulatory requirements.

By obtaining a plant operating permit, you will gain confirmation of compliance, understand required operator qualifications, and enable more effective safety oversight. This also facilitates more efficient tracking of power engineer’s professional work experience (firing time) and linkage to the plants they operate.

Individual Component Requirements

Are we still required to obtain operating permits for the individual components of regulated pressure equipment?

Yes, the operating permits for plants are in addition to operating permits for regulated equipment, such as boilers, pressure vessels, heat exchangers, and refrigeration units. Single, large boilers qualifying as plants will require both an operating permit and a plant operating permit.

How Do I Find Out the Classification of My Plant?

Through the online registration process, your plant type and classification will be determined. Before starting the process, please check the plant type classification to determine if your plant needs to be registered.

We will also confirm the accuracy of your plant classification as part of the application process.

How Long Does the Application / Review Process Take?

The online application process will take anywhere from 15 minutes to an hour, depending on the size and intricacies of your plant. After you submit your application, we will assess the information to ensure compliance. The time we will require to review your application and issue the plant operating permit will depend upon the completeness, accuracy, and complexity of the application, as well as the number of applications currently being processed.

Related Information

Boiler Plant Program

Learn about the Boiler Plant Program and how to register your plant.

Learn MoreBoilers and Pressure Vessels

Learn about who needs an operating permit for boilers and pressure vessels.

Learn More